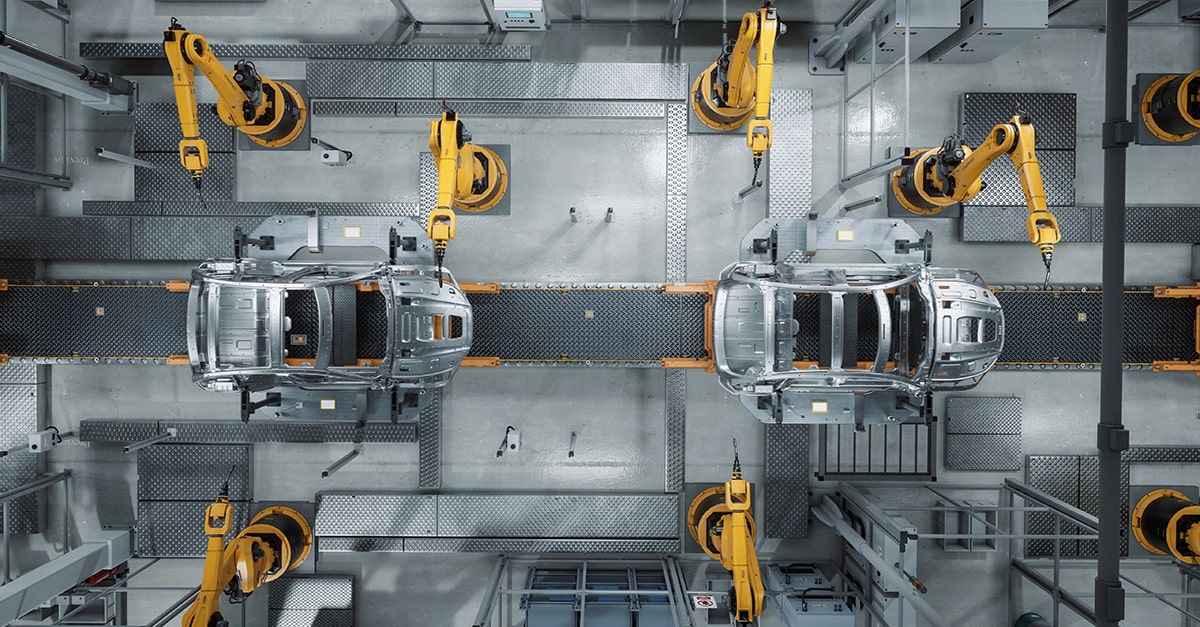

How Modularization Can Help Vehicle Producers Making the Shift to Electric Drives

Climate targets and rising sustainability demand necessitate shifting from combustion engines to electric drives. This shift in the automotive industry will extend to other industries like aircraft an...

READ MORE »